Domestic

LLDPE

LLDPE (Linear Low Density Polyethylene) This is the primary type of resin used in modern can liner manufacturing technology. Bags made from LLDPE film provide excellent combination of film strength, puncture resistance and tear resistance. LLDPE is the preferred resin for injection molding because of its superior toughness and is used in items such as PLASTIC WATER TANKS, ROAD BARRIERS, Grocery Bags, Garbage Bags and Landfill liners

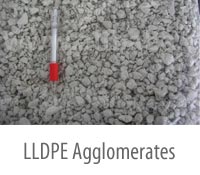

Properties of ROTO (LLDPE) GRADE – AGGLO:

| S no. | Specification | Nominal Value Unit |

| 1. | Hardness | 55 |

| 2. | Density | 0.940 g/cm3 |

| 3. | Environmental Stress-Cracking Resistance (10% lpegal) | >300 hr |

| 4. | Melt Flow Index (190ºC / 2.16 Kg) | 3.5 – 4.5 / 10 min |

| 5. | Tensile Strength ( Yield, 2.00 mm) | > 20.0 Mpa |

| 6. | Elongation (Yield) | > 250 % |

| 7. | Flexural Modulus (3.20 mm , Compression Moulded) | > 600 Mpa |

| 8. | Notched Izod Impact (3.20 mm , Injection Moulded) | 50 J/m |

|

|

|

|

USAGE of LLDPE AGGLOMERATES

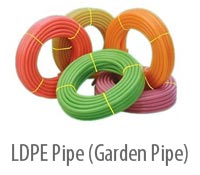

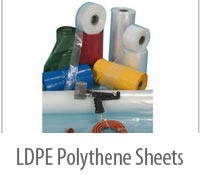

LDPE

LDPE - Low-density polyethylene (LDPE) is a thermoplastic made from petroleum. It was the first grade of polyethylene, produced in 1933 using a high pressure process via free radical polymerisation.

LDPE is marked with the resin identification code of 4. LDPE is flexible, tough, and almost unbreakable. It's perfect for products that need a good squeeze

.gif) |

|

|

|

USAGE of LDPE AGGLOMERATES

What is Agglomerates?

Agglomerates are synonymous word to GRINDING. Imported Plastic Film Scrap after careful segregation and removal of impurities like Tapes & Stickers by SKILLED WORKERS is grinded in AGGLOMERATOR MACHINE. The product thus obtained is AGGLOMERATES (AGGLO)

Agglo v/s Granules

- INCREASE OF COST: Conversion of AGGLO to GRANULES increases COST by Rs 4 / Kg.

- LESS DEPENDENCY IN QUALITY OF GRANULES : During Conversion of Agglo to Granules : Talc Powder, Moisture Powder, Wax, Low Quality LDPE and many more things can be blended and hence QUALITY OF GRANULES is not dependable

- DIRECT USAGE of AGGLO in :

* Roto Molding Process for Water Tanks

* Road Barriers

* Manufacturing of Tarpaulins

* Blending in EVA

* Manufacturing of Masterbatch

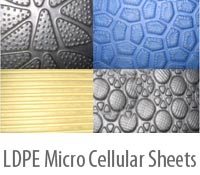

* Manufacturing of Footwear Sheets

* Usage for different Compounding process

Quality Assurance

Unlike most of the Re-process unit we give huge importance to our R&D Unit to ensure standard material each and every time. All our material and product lots pass through multi stage before and after the production process. Our plastic engineers and expert s are working very hard to improve product in area of higher flexibility, better impact strength, long term crack resistance and many other aspects. Hence, Sun Group of Industries ensures you really standard material with 99% perfection and uniformity each and every time you use it.

Unlike most of the Re-process unit we give huge importance to our R&D Unit to ensure standard material each and every time. All our material and product lots pass through multi stage before and after the production process. Our plastic engineers and expert s are working very hard to improve product in area of higher flexibility, better impact strength, long term crack resistance and many other aspects. Hence, Sun Group of Industries ensures you really standard material with 99% perfection and uniformity each and every time you use it.

Quality is the prime focus of the organization as it compels the customers to buy a product. For maintaining high standard of quality, we use superior raw materials like plastic scraps, additives, chemicals, etc. for manufacturing and conduct stringent check on every stages of production. To assure the quality process we used the process and machine like MFI Machine, Tensile Strength, Dart Impact Test, Density Test etc.

Melt Flow Indexer

Melt Flow Indexer

The Melt Flow Index is a measure of the ease of flow of the melt of a thermoplastic polymer. It is defined as the mass of polymer in grams flowing in 10 minutes through a capillary of specific diameter and length by a pressure applied via prescribed alternative gravimetric weights for alternative prescribe d temperatures. The melt flow rate is an indirect measure of molecular weight, high melt flow rate corresponding to low molecular weight. Synonyms of Melt Flow Index are Melt Flow Rate and Melt Index. Actually more commonly used are their abbreviations: MFI, MFR and MI

Laboratory Density Meter

The laboratory Density meter is the most accurate density meter on the market and is ideal for numerous fields of application and successful continuous operation in the laboratory. First Class Digital Density Measurement provided by the robust DMA Generation M density meters is applied in industrial quality control, in research, at authorities and standard organizations. This series of density meter provides unparalleled ease-of-use at an attractive price and ensure complete transparency and traceability of the sample filling and measurement process.

Digital Tensile Strength Tester

Digital Tensile Strength Tester

Tensile strength and elongation are the two prime characteristics of the most of the raw materials, whether they are metals or non-metals such as rubber, leather, textiles, plastic paper or finished products such as rods, wires, ropes, yarns, belts etc. These properties very often play the major role in determining the suitability of any raw material of any specific applications. It is, therefore of utmost importance to determine these characteristics accurately, conveniently and quickly. The tensile testing provides a relatively inexpensive for determining the tensile strength and elongation of a variety of raw materials, they are based on constant rate of traverse principle in which one end of the test specimen is held in a and screw arrangement.

Dart Impact Test Machine

Dart Impact Test Machine

The Falling Dart Impact Tester is intended for the determination of mechanical properties of packaging material such as plastic films, laminates and paper. The tester comprises a horizontal base-plate on which a vertical column of steel has been erected and which on its top carries a release mechanism in which the falling dart can be inserted. Falling Dart Impact tester is applicable in falling Dart Impact Test that causes plastic films and foils to fail under specified conditions of impact of a free falling Dart.